Unlocking Precision: Onto Innovation’s Atlas G6 Metrology Breakthrough

Discover how Onto Innovation’s Atlas G6 optical metrology system revolutionizes AI-era semiconductor process control with unmatched precision, smaller spot sizes, and faster optimization for next-gen chip manufacturing.

Key Takeaways

- Atlas G6 delivers smaller spot sizes for precise nanoscale measurements

- Advanced optics and AI-driven software speed up process optimization

- Onto Innovation secured $20M in new orders, mostly for Q4 revenue

- The system targets next-gen GAA logic and high-bandwidth memory chips

- Geopolitical and margin pressures challenge Onto despite tech leadership

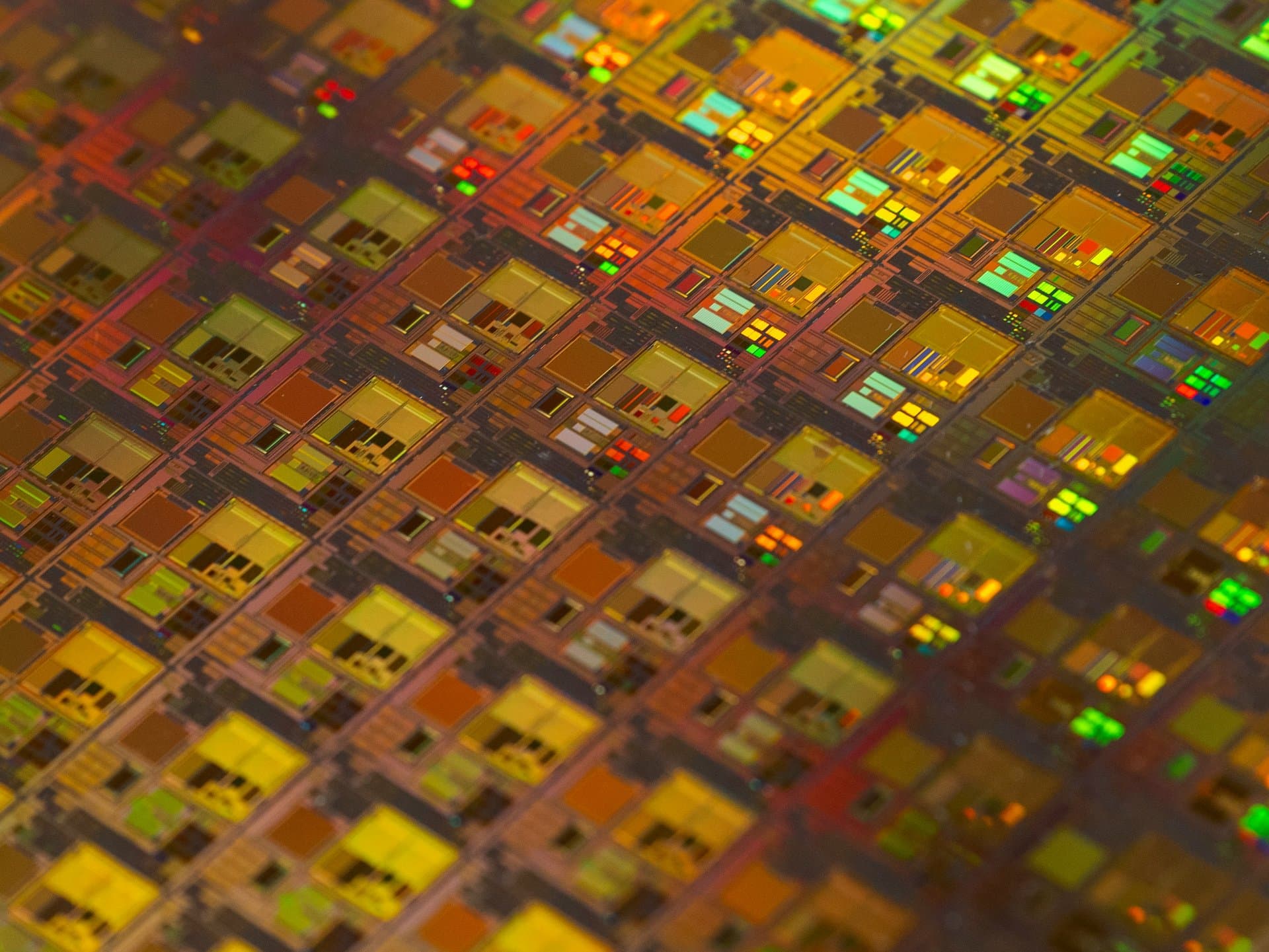

In the fast-evolving world of semiconductors, precision is king. Onto Innovation’s latest marvel, the Atlas G6 Optical Critical Dimension (OCD) Metrology System, steps into the spotlight as a game-changer for AI-era chip manufacturing. Designed to tackle the microscopic challenges of next-generation gate-all-around (GAA) transistors and high-bandwidth memory (HBM), the Atlas G6 promises sharper accuracy and faster process control.

As AI and data-intensive applications push chipmakers to shrink device features by up to 30% each cycle, traditional measurement tools struggle to keep pace. Onto’s Atlas G6 answers this call with smaller optical spot sizes and enhanced signal clarity, enabling direct measurements on the tiniest nanowires and DRAM cell blocks. This leap in metrology technology is already winning multiple production orders from leading semiconductor manufacturers.

This article dives into the Atlas G6’s technical innovations, its role in AI-driven semiconductor production, and the broader market forces shaping Onto Innovation’s journey. Buckle up for a deep yet accessible look at how precision measurement tools are quietly powering the future of technology.

Meeting AI’s Nanoscale Demands

AI’s hunger for speed and efficiency is reshaping chip design. Next-gen gate-all-around (GAA) transistors, with their nanowire channels, and high-bandwidth memory (HBM) stacks demand measurement tools that can see the unseen. Imagine trying to measure a single strand of hair—but at the nanoscale. That’s the challenge Onto Innovation’s Atlas G6 tackles head-on.

Each semiconductor cycle tightens dimensional tolerances by up to 30%, pushing manufacturers to measure features smaller than ever before. Traditional tools falter here, but the Atlas G6’s smaller optical spot size and enhanced signal-to-noise ratio allow it to peer directly onto these tiny structures without losing clarity. This means better control over the manufacturing process, higher yields, and chips that perform reliably in AI applications.

The stakes are high. As AI chips become more complex, the margin for error shrinks. The Atlas G6’s precision isn’t just a technical upgrade—it’s a necessity for the future of computing power.

Innovating with Optics and AI

What sets the Atlas G6 apart? It’s a blend of cutting-edge optics and smart software. The system’s reengineered optics deliver a smaller spot size with improved spectral stability, boosting measurement precision. Think of it as upgrading from a blurry camera to a high-definition lens.

But hardware is only half the story. Onto’s proprietary Ai Diffract™ software uses machine learning algorithms to analyze data faster and more accurately. This AI-driven approach accelerates recipe development—the step where measurement parameters are fine-tuned—cutting time to solution and improving robustness. It’s like having a seasoned expert guiding every measurement in real time.

This synergy of optics and AI enables the Atlas G6 to maintain fleet-wide consistency across fabs, ensuring that measurements are reliable no matter where or when they’re taken. For manufacturers, this means less guesswork and more confidence in their process control.

Driving Market Momentum Amid Challenges

Onto Innovation’s Atlas G6 has already attracted multiple production orders from leading logic and memory chipmakers, signaling strong market demand. The company booked over $20 million in new orders for Atlas OCD and Iris films, with most revenues expected in the fourth quarter. This momentum reflects the industry’s urgent need for advanced metrology tools as AI chips become mainstream.

Yet, Onto faces headwinds. U.S.-China trade tensions impose tariffs adding $2 to $3 million in costs for upcoming quarters, squeezing margins. Gross margin guidance stands at 53-55%, down a point due to tariffs, while operating margins are expected to dip amid rising R&D expenses and lower revenues. Additionally, revenue concentration risk looms, with the top three customers accounting for 52% of 2024 sales.

Despite these pressures, Onto’s diversified product portfolio—including the Dragonfly 3Di platform and Iris G2 films—supports its growth strategy. The company’s ability to innovate and secure key customer wins will be critical in navigating this complex landscape.

Challenging Metrology Myths

Metrology in semiconductor manufacturing often gets boxed into the myth that bigger is better—bigger tools, bigger data sets, bigger budgets. The Atlas G6 flips this notion on its head by proving that smaller spot sizes and smarter analysis trump brute force. Precision, not size, drives yield and performance.

Another myth is that AI integration in manufacturing is futuristic hype. Onto’s Ai Diffract™ engine demonstrates that machine learning is already a practical, game-changing tool in process control. It’s not about replacing human expertise but amplifying it—speeding up recipe development and reducing errors.

Finally, some believe that metrology tools are one-size-fits-all. The Atlas G6’s tailored design for GAA and HBM devices shows that specialized solutions are essential as chip architectures evolve. This challenges the idea that legacy tools can simply be repurposed for next-gen demands.

Navigating the Future of Chipmaking

The semiconductor industry stands at a crossroads where AI-driven complexity meets manufacturing precision. Onto Innovation’s Atlas G6 is a beacon in this landscape, offering tools that don’t just measure but predict and optimize.

Integration with Onto’s Discover® ecosystem enables predictive process control and smart manufacturing, accelerating yield improvements. This holistic approach is vital as fabs juggle tighter tolerances and faster production cycles.

While geopolitical and economic challenges persist, the Atlas G6’s technological edge positions Onto as a leader in semiconductor metrology. For chipmakers racing to meet AI’s insatiable demand, tools like the Atlas G6 aren’t optional—they’re the foundation of tomorrow’s breakthroughs.

Long Story Short

Onto Innovation’s Atlas G6 isn’t just another metrology tool—it’s a precision instrument crafted for the semiconductor industry’s most demanding era. By shrinking spot sizes and harnessing AI-powered analysis, it enables chipmakers to tame the complexities of GAA transistors and HBM architectures with unprecedented accuracy. Yet, the road ahead isn’t without hurdles. Trade tensions and margin pressures loom, reminding us that even breakthrough technology must navigate a challenging economic landscape. Onto’s ability to secure significant orders and integrate smart manufacturing ecosystems positions it well, but sustained innovation and strategic partnerships will be key. For investors and tech enthusiasts alike, the Atlas G6 story underscores a vital truth: in the race for AI supremacy, precision measurement is the unsung hero. The relief of tighter process control, higher yields, and smarter fabs is a quiet revolution—one that Onto Innovation is helping lead with confidence.