T1 Energy and Corning Unlock Fully American-Made Solar Panels

Discover how T1 Energy and Corning’s $6B deal crafts a fully American-made solar panel supply chain, boosting U.S. energy security, creating 6,000 jobs, and slashing costs by 20% by 2030.

Key Takeaways

- T1 and Corning create the first fully American solar panel supply chain

- The $6 billion deal spans polysilicon to finished panels

- 6,000 new jobs will boost Michigan and Texas economies

- Solar module costs expected to drop 15-20% by 2030

- The partnership aligns with the 2024 OBBBA federal law

- Energy security improves by reducing reliance on foreign suppliers

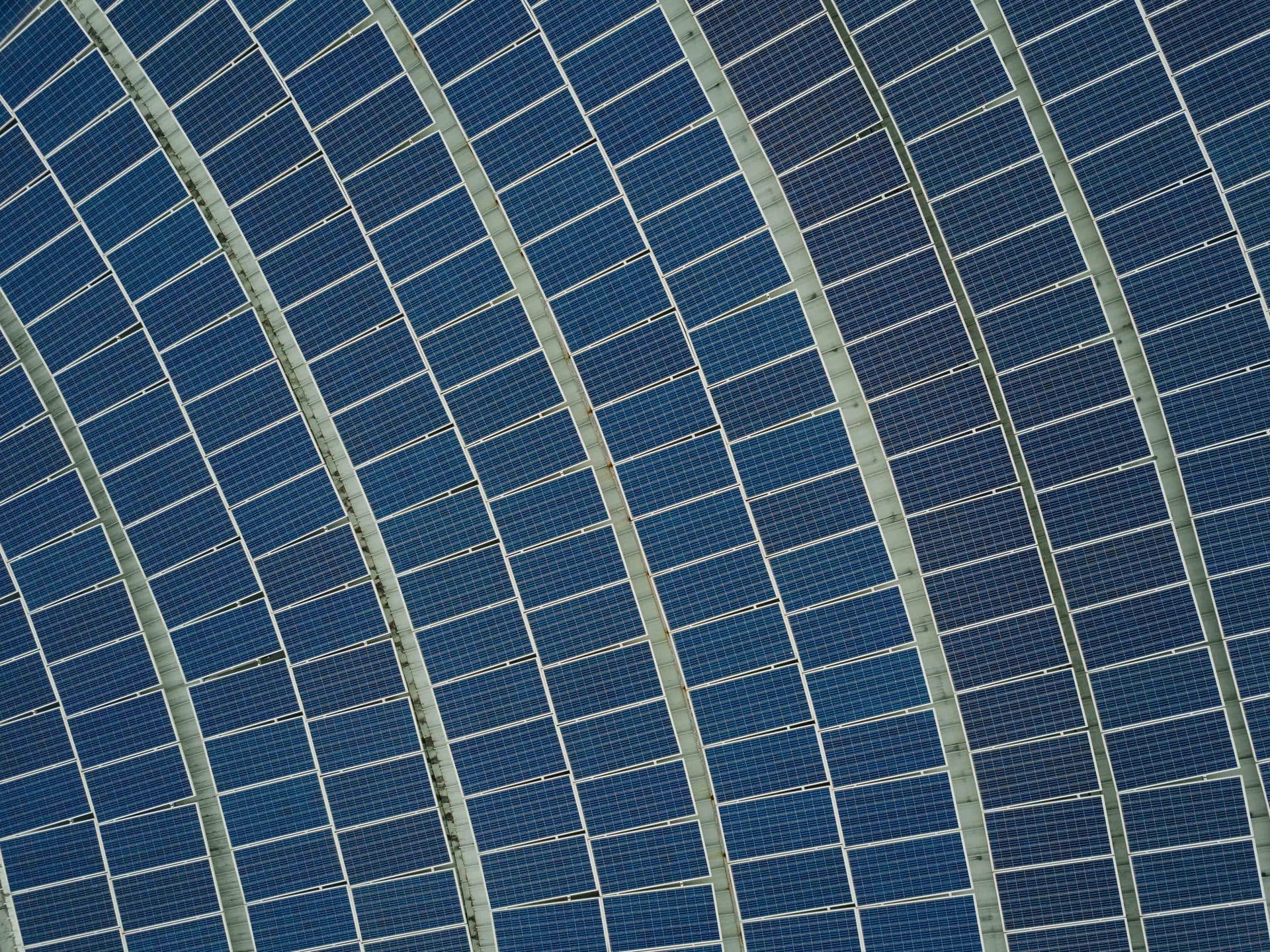

Imagine a solar panel born and bred entirely in the United States—from the silicon in Michigan to the final assembly in Texas. That’s exactly what T1 Energy and Corning Incorporated are building with their landmark $6 billion partnership. This deal isn’t just about business; it’s a strategic response to the 2024 One Big Beautiful Bill Act (OBBBA), which demands American-made components for federal clean energy tax credits. With China dominating global solar wafer production, this alliance rewrites the rules, creating a vertically integrated supply chain that promises 6,000 new jobs and a 15-20% cost reduction by 2030. Let’s unpack how this bold move reshapes U.S. solar manufacturing, energy security, and the future of clean power.

Building a Domestic Solar Chain

Picture the solar panel’s journey starting in Michigan, where Corning’s advanced facilities churn out hyper-pure polysilicon—the essential ingredient for solar wafers. These wafers, thin as a whisper, are the solar panel’s DNA, capturing sunlight and converting it into electricity. Starting in late 2026, these wafers will travel to T1 Energy’s new Austin facility, where they’ll be transformed into solar cells. Finally, these cells will find their way to T1’s Dallas plant for assembly into finished solar modules. This seamless, fully American-made supply chain is a rarity in an industry long dependent on Asian imports, especially from China. It’s like crafting a gourmet meal entirely from local ingredients, ensuring freshness, quality, and traceability.

This vertical integration isn’t just about pride—it’s a strategic shield. By controlling every step domestically, T1 and Corning sidestep the vulnerabilities of global logistics snarls and geopolitical tensions. The supply chain certainty this creates is a game-changer for U.S. solar developers, who can now plan projects without the looming shadow of foreign disruptions. It’s a bold statement: America can build its solar future on home soil, with homegrown materials and workers powering the green revolution.

Navigating New Federal Rules

The One Big Beautiful Bill Act (OBBBA) of 2024 is the catalyst behind this American solar renaissance. This law ties federal clean energy tax credits to the use of U.S.-made equipment, effectively barring projects that rely on foreign components, especially from China, from receiving these incentives. For solar companies, this is a seismic shift—adapt or risk losing vital financial support.

T1 Energy and Corning’s deal is a direct answer to this challenge. By ensuring every core component—from polysilicon to panels—is made domestically, they guarantee eligibility for these tax credits. This isn’t just compliance; it’s a competitive edge. The policy nudges the entire industry toward reshoring, accelerating investments in U.S. manufacturing infrastructure. It’s a reminder that policy can be a powerful driver of economic transformation, turning regulatory hurdles into opportunities for growth and innovation.

Creating Jobs and Economic Growth

Behind the gleaming solar panels lies a workforce of about 6,000 Americans spread across Michigan and Texas. These aren’t just factory jobs; they’re skilled positions in advanced manufacturing, engineering, and operations. For communities in these states, this partnership is a lifeline, injecting vitality into local economies and supporting workforce development.

The ripple effects extend beyond direct employment. Local suppliers, service providers, and ancillary industries stand to benefit from the increased activity. This job creation story counters the myth that clean energy investments are just about technology—at their heart, they’re about people. The pride of building something tangible, something that powers homes and businesses, resonates deeply. It’s a reminder that economic growth and environmental stewardship can walk hand in hand.

Cutting Costs with Scale and Integration

Cost is king in solar energy, and T1-Corning’s vertically integrated supply chain promises to trim prices by 15 to 20 percent by 2030. How? By shortening supply lines, reducing reliance on foreign imports, and harnessing scale advantages. Think of it as streamlining a relay race—fewer handoffs mean fewer delays and less waste.

This cost reduction narrows the gap between American-made solar panels and their foreign competitors, making domestic options more attractive to utilities and businesses. It challenges the myth that ‘Made in America’ means expensive or inefficient. Instead, it shows that with smart partnerships and policy support, U.S. manufacturers can compete on price and quality. The result? More affordable clean energy for all, fueling broader adoption and accelerating the transition to a low-carbon future.

Strengthening Energy Security

Energy security often feels like a buzzword, but this deal gives it real teeth. By reducing dependence on foreign suppliers—especially China, which dominates solar wafer production—the U.S. shields its solar industry from geopolitical shocks, trade disputes, and supply chain disruptions.

This resilience is vital as electricity demand surges, driven by AI, data centers, and electrified infrastructure. The T1-Corning alliance ensures that America’s solar backbone won’t buckle under external pressures. It’s a strategic move that aligns clean energy leadership with national security priorities. For policymakers, investors, and consumers, it’s reassurance that the lights will stay on, powered by panels proudly made on American soil.

Long Story Short

The T1 Energy and Corning partnership is more than a manufacturing milestone—it’s a blueprint for American energy independence. By weaving together every step of solar panel production domestically, they’re cutting supply chain risks, creating thousands of jobs, and making clean energy more affordable. For U.S. solar developers and utilities, this means reliable access to fully American-made panels that comply with federal tax incentives. The relief of a stable, homegrown supply chain can’t be overstated in a world of geopolitical uncertainty. As the solar industry embraces this new era, expect ripple effects across manufacturing sectors, fueling innovation and economic growth. For investors, workers, and clean energy advocates alike, this deal signals that the future of solar power is not just green—it’s proudly American.