Schaeffler and Neura Robotics Unlock Humanoid Automation Future

Discover how Schaeffler’s strategic partnership with Neura Robotics is pioneering humanoid robotics integration in industrial automation, promising thousands of AI-driven robots by 2035 to reshape manufacturing efficiency.

Key Takeaways

- Schaeffler plans thousands of humanoids by 2035

- Partnership blends precision mechanics with AI learning

- Digital twins and simulation speed robot deployment

- Early trials prove humanoids handle complex tasks

- AI-driven Physical-AI ecosystem fuels continuous robot improvement

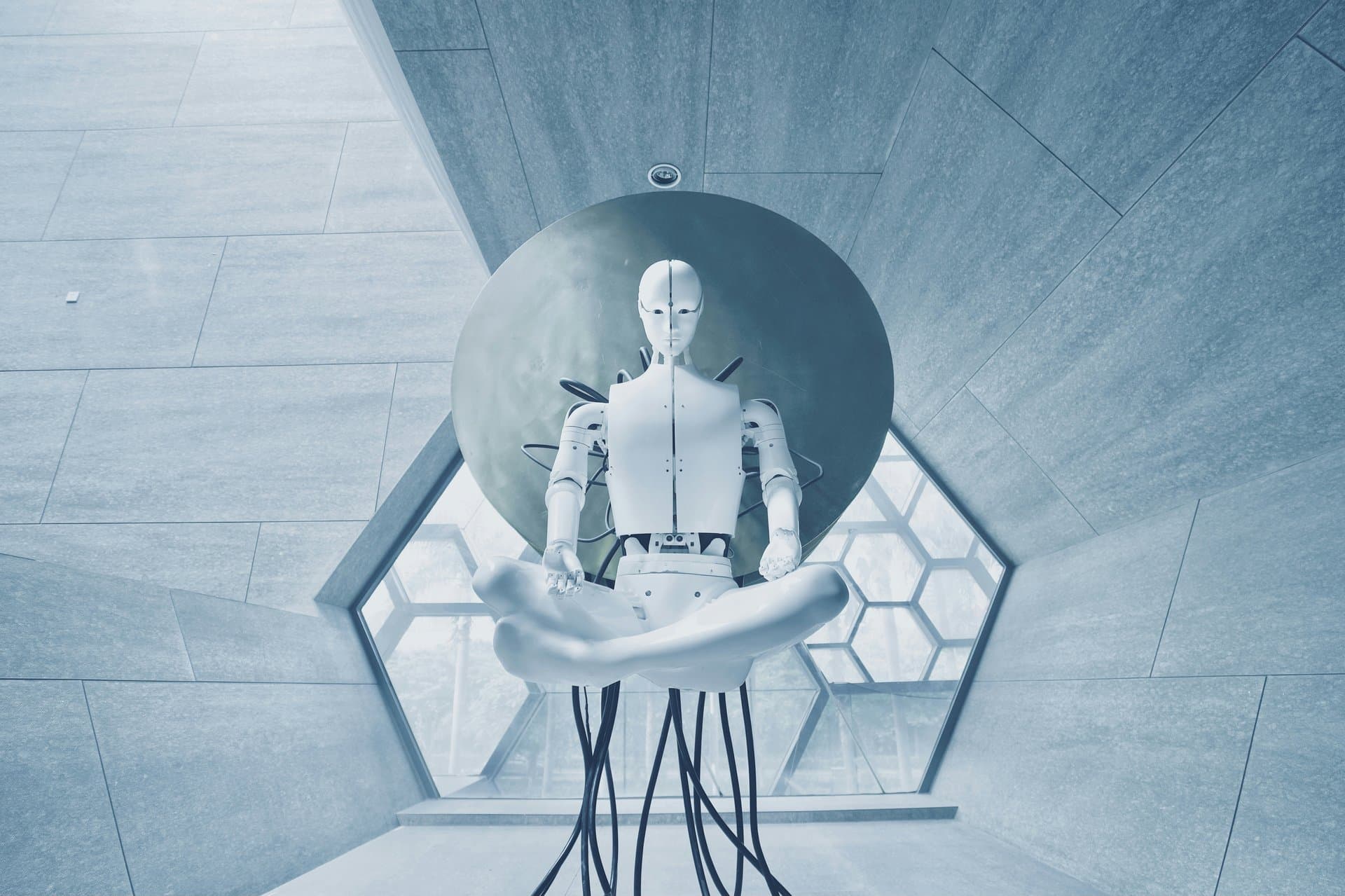

Imagine a factory floor where humanoid robots work side-by-side with humans, handling logistics, assembly, and material tasks with precision and adaptability. This vision is becoming reality as German industrial giant Schaeffler AG teams up with Neura Robotics to develop and deploy thousands of humanoid robots by 2035. This partnership marries Schaeffler’s mechanical expertise with Neura’s cutting-edge AI to revolutionize industrial automation.

Facing challenges like tariff pressures and shifting markets, Schaeffler is betting on innovation to fuel growth beyond traditional automotive sectors. Their focus on AI-driven humanoids reflects a broader trend of digital transformation and efficiency optimization in manufacturing. Through digital twins, simulation, and real-world data feedback, these robots will learn and adapt faster than ever.

In this article, we’ll explore how this partnership is reshaping factory automation, the technology powering humanoid robots, and what this means for the future of industrial efficiency. Buckle up for a journey into the next frontier of robotics and AI integration.

Forging a Strategic Partnership

Schaeffler AG, known for its automotive and industrial prowess, has joined forces with Neura Robotics, a trailblazer in humanoid and cognitive robotics. This isn’t your typical supplier deal; it’s a strategic partnership aimed at co-developing key components and integrating humanoid robots on a massive scale. By 2035, Schaeffler plans to embed thousands of these robots into its production network, signaling a seismic shift in factory automation.

Why now? Europe’s auto industry faces stiff headwinds—tariffs, weaker demand, and fierce competition from Chinese firms. Schaeffler’s response is to diversify and innovate, targeting new sectors like defence, electric vertical take-off aircraft, and humanoid robotics for up to 10% of sales by 2035. This partnership embodies that pivot, blending Schaeffler’s mechanical expertise with Neura’s AI-driven robotics.

CEO Klaus Rosenfeld highlights the dual nature of this investment: boosting internal efficiency and unlocking new business potential through AI-powered humanoids. It’s a calculated leap, not a gamble, reflecting a clear-eyed approach to future-proofing manufacturing.

Building Robots with Precision

At the heart of humanoid robotics lies precision mechanics, and Schaeffler brings decades of expertise to the table. Their specialty? Planetary gear actuators—compact, reliable components that give robots the fine motor skills needed to mimic human dexterity. Think of these actuators as the robot’s joints, enabling smooth, accurate movements essential for tasks like assembly or material handling.

Neura Robotics complements this with its AI-driven cognitive systems, creating a Physical-AI ecosystem where robots learn from real-world data. This synergy means robots don’t just follow pre-set commands; they adapt and improve on the fly, responding to changing factory conditions. It’s a leap beyond traditional automation, where rigidity often limits flexibility.

This blend of hardware and AI is the secret sauce powering Schaeffler’s vision of humanoids that can handle complex, repetitive, or hazardous tasks with human-like finesse.

Harnessing Digital Twins and Simulation

Deploying thousands of humanoid robots isn’t as simple as flipping a switch. Schaeffler leverages digital twins—virtual replicas of factories and robots—to simulate and optimize every detail before physical rollout. Using platforms like NVIDIA Omniverse, they create immersive, AI-powered models that test workflows, layouts, and robot behaviors in a risk-free environment.

This virtual commissioning accelerates deployment, slashing time and costs while ensuring robots perform flawlessly from day one. Humanoids are trained through imitation learning, where vision AI captures human and robot movements to teach robots intricate tasks. This simulated practice grounds the robots in reality, making their transition to the factory floor smoother.

The result? A factory ecosystem where digital and physical worlds intertwine, enabling continuous improvement and rapid adaptation to new challenges.

Validating with Real-World Trials

Theory meets practice in Schaeffler’s early proof-of-concept trials, where pre-alpha humanoid robots have successfully performed bin picking and material handling. These tasks, often repetitive and detail-oriented, are perfect testbeds for humanoids aiming to relieve human workers from mundane labor.

The trials demonstrate that these robots can learn from both simulated environments and real interactions, refining their skills through continuous feedback. This hands-on validation is crucial—it proves that the partnership’s ambitious vision isn’t just futuristic hype but grounded in tangible results.

Such early successes build confidence that humanoids can handle complex logistics, kitting, and assembly tasks, setting the stage for broader industrial adoption.

Shaping the Future of Automation

Schaeffler and Neura Robotics are charting a course toward a new industrial era where humanoid robots are not just tools but adaptive partners. This partnership’s strategic focus on scalable, AI-driven solutions addresses the pressing need for efficiency and flexibility in a challenging market.

By integrating real-time operational data, they create a feedback loop that continuously enhances both hardware and software performance. This dynamic approach ensures robots evolve alongside factory demands, reducing downtime and boosting productivity.

As the partnership matures, it promises to set new standards for humanoid deployment in manufacturing and logistics, inspiring industries worldwide to rethink automation’s possibilities.

Long Story Short

The Schaeffler-Neura Robotics alliance is more than a tech collaboration—it’s a bold step toward a future where humanoid robots become integral factory teammates. By 2035, thousands of these AI-powered helpers will transform production lines, boosting flexibility and cutting costs in a challenging global market. This partnership’s strength lies in blending mechanical precision with AI’s learning prowess, supported by digital twins and simulation that shrink deployment times and ramp up robot capabilities. Early successes in material handling prove the concept’s viability, setting the stage for broader adoption. For industries watching this space, the message is clear: embracing humanoid robotics isn’t just innovation—it’s survival and growth. The relief of streamlined operations and the excitement of AI-driven adaptability await those ready to step into this new era of industrial automation.